Textiles Definitions

This is a list of textile definitions that might help if you hear textile words and phrases that people are using in the textiles field.

To search, hold the control key on your keyboard and while you’re holding it tap the “F” key. This should bring up the find menu where you can type your search in and press enter.

There will be another list of embroidery specific definitions coming soon!

Abraded Yarn

Adherend

A body that is held to another body, usually by an adhesive

Adhesive Failure

Rupture of an adhesive bond such that the separation appears to be at the adhesive-adherend interface

Adhesive Strength

Strength of the bond between an adhesive and an adherend

Air-bubble void

Air entrapment within an between the plies of reinforcement or within a bond line or encapsulated area localized and non interconnected

Air forming

A process in which air is used to separate and move fibers to fashion a web

Air Jet Spinning

A spinning system in which yarn is made by wrapping fibers around a core stream of fibers with compressed air in this process the fibers are drafted to appropriate sliver size then fed to the air jet chamber where they are twisted, first in one direction then in the reverse direction in a second chamber They are stabilized after each twisting operation.

Air-laid nonwovens

Fabrics made by an air forming process. The fibers are distributed by air currents to give random orientation with the web and a fabric with isotropic properties.

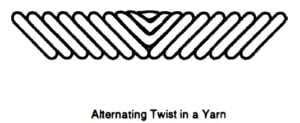

Alternating Twist

A yarn in which the twist alternates between S type and Z type along the length of the yarn. Sometimes called false twist.

Angle-Ply Laminate

A laminate formed with fibers of adjacent plies oriented at alternating angles

Anisotropic

Having different properties in every direction in the plane of a fabric, it is related to a nonrandom distribution of fibers

Areal Weight

The weight of fiber per unit area of a tape or fabric typically expressed as grams per meter squared or oz per yard squared.

Autoclave

An apparatus for carrying out certain finishing operations such as bleeding heat setting under pressure in a super heated steam atmosphere. Alternatively an apparatus for polymerizing condensation polymers such as nylon or polyester at any pressure above or below atmospheric.

Automatic press

A hydraulic press for compression molding or an injection machine that operates continuously being controlled mechanically electrically hydraulically or by a combination of any of those methods

Axial Yarn

A yarn running purely in the zero direction of a fabric or warp direction. This yarn has no intentional crimp. Alternatively this is the system of longitudinal yarns in a Tri axial braid that are inserted between bias yarns.

Balanced Twist

In applied yarn or cord an arrangement of twist which will not cause the yarn or cord to twist on itself or kink when held an open loop. A single ply is twisted in a particular direction either S or Z, and several plies are twisted together in the opposite direction either Z or S , so that the final yarn structure has no net residual torque.

Balling Up

A defect in which loose or frayed fibers form into a ball and are then woven into the fabric.

Ball Warp

Parallel threads in the form of a twist less rope wound into a large ball. When wound mechanically with a quick transverse, a ball warp may be made in the form of a large cylindrical package.

Ban

Another name for a yarn creel

Base Fabric

In coated fabrics, the underlying substrate

Basket Stitch

A knit construction in which purl and plain loops are combined with a preponderance of purl loops in the pattern courses to give a basket weave effect.

Basket Weave

A variation of the plain weave in which two or more warp and filling threads are woven side-by-side to resemble a plaited basket. Fabrics have a loose construction and a flat appearance and are used for things such as monk’s cloth and drapery fabric.

Batting

A soft bulky assembly of fibers usually carted. Battings are sold in sheets or rolls and are used for warm interlinings, comforter stuffing, and other thermal or resiliency applications.

Beaded Selvage

A weaving defect at the salvage of excessive thickness or irregular filling loops that extend beyond the outside salvages.

Beam

A cylinder of wood or metal, usually with a circular flange on each end, on which a warp yarns are wound for slashing, weaving, or warp knitting.

Beating-Up

The last operation of the loom in weaving, in which the last pick inserted in the fabric is “beat” into position against the preceding picks.

Bending Length

A measure of fabric stiffness based on how the fabric bends in one plane under the force of gravity.

Bending Modulus

Stress a specimen can withstand when bent a unit deflection. For fibers the stress per unit of linear fiber weight required to produce a specified deflection of a fiber.

Bending Rigidity

This measure of a materials resistant to bending is calculated by multiplying the materials weight per unit area by the cube of its bending length.

Bias Fabric

A 2D textile fabric that when oriented in the XY plane contains fibers that are aligned in a different direction for example 45 degrees to the X axis.

Bias Filling

A fabric defect in which the filling yarn does not run at a right angle to the warp. The principal cause is improper processing on that tenter frame.

Biconstituent Fiber

A fiber extruded from a homogeneous mixture of two different polymers. Such fibers combine the characteristics of the two polymers into a single fiber.

Bi-directional Fabric

A fabric which has reinforcing fibers in two different directions such as the warp direction and the filling or weft direction.

Bilaterial Fibers

Two generic fibers or variants of the same generic fiber extruded in a side-by-side relationship.

Binder

An adhesive applied with a solvent or a soft and pliable plastic melted to bond fibers together in a web or to bind one web to another web.

Binder Fibers

Fibers that act as an adhesive in a web because their softening point is relatively low compared with that of the other fibers in the material.

Blister

A bulge resulting from separation of coating or laminating material from the base fabric

Bobbin

A cylindrical or slightly tapered barrel with or without flanges for holding slubbing’s, roving’s, or yarns.

Bolt

A roll or piece of fabric of varying length

Bonded Fabric

A fabric containing two or more layers of cloth joined together with resin, rubber, foam, or adhesive to form one ply.

Bonding

A process for adhesive laminating two or more fabrics or a fabric and a layer of plastic foam. There are two methods: the flame method used for bonding foam and the adhesive method used for bonding face and backing fabrics. Alternatively, it could be one of several processes of binding fibers into thin sheets webs or batting’s by means of adhesive plastics or cohesion.

Bonding with binder fibers

Specifically designed low melting point fibers are blended with other fibers in a web so that uniformly bonded structures can be generated at a low temperature by Fusion of the binder fiber with adjacent fibers.

Point Bonding

The process of binding thermoplastic fibers into a nonwoven fabric by applying heat and pressure so that the discrete pattern of fibers is formed also called spot bonding.

Print Bonding

A process of binding fibers into a nonwoven fabric by applying an adhesive in a discrete pattern

Spray Bonding

A process of binding fibers into a nonwoven fabric involving the spray application of a fabric binder.

Stitch Bonding

A bonding technique used for the fabrication of nonwovens in which the fibers are connected by stitches sewn or knitted through the web also known as quilting.

Bow

The greatest distance measured parallel to the selvage between a yarn and a straight line drawn between the points at which this yarn meets the selvages. Bow may be expressed directly in inches or as a percentage of the width of the fabric at that point.

Box Loom

A loom using two or more shuttles for weaving fabrics with filling yarns that differ in fiber type, color, twist level, or yarn size. The box motion is automatic, changing from one shuttle to another.

Box Mark

A fine line parallel to the filling caused by shuttle damage to a group of filling yarns.

Braid

1. A narrow textile band, often used as trimming or binding, formed by plaiting several strands of yarn. The fabric is formed by interlacing yarns diagonally to the production of the material. 2. In aerospace textiles, a system of three or more yarns which are interlaced in such a way that no two yarns are twisted around each other.

Biaxial Braid

Braided structure with two yarn systems one running in one direction and the other in the opposite direction.

Triaxial Braid

A braided fabric structure which includes axial yarns running in the longitudinal direction. The axial yarns a.re entrapped within a bra.id intersection. The maximum number of axial yarns which may be included in the fabric is one half the number of braiding yarns.

Brushing

A finishing process in which rotating brushes raise a nap on knit or woven fabrics.

Bundle

A general term for a collection of essentially parallel filaments or fibers

Burling

The process of removing loose threads and knots from fabrics with a type of tweezers called a burling iron. 2. The process of correcting loose tufts and replacing missing tufts following carpet construction.

Cabled Yarn

A yarn formed by twisting together two or more plied yarns.

Calendar

A machine used in finishing to impart a variety of surface effects to fabrics. A calendar essentially consists of two or more heavy rollers, sometimes heated, through which the fabric passes under heavy pressure.

Calendaring

A mechanical finishing process for fabrics to produce special effects, such as high luster, glazing, moire, and embossed effects. In this operation, the fabric is passed between heated rolls under pressure.

Calendar Rolls

1. The main cylinders on a calendar 2. Smooth or fluted rolls used on various fiber processing machines such as pickers and cards to compress the lap or sliver as it passes between them.

Can

A cylindrical container about 3 feet high and 10 or 12 inches in diameter, that is used to collect sliver delivered by a card, drawing frame, etc .

Carbon-carbon

A composite material consisting of carbon and graphite fibers in a carbon or graphite matrix.

Carbon Fiber

Fiber produced by the pyrolysis of organic precursor fibers, such as rayon, polyacrylonitrile (PAN), and pitch, in an inert environment. The term is often used interchangeably with graphite; however, carbon fibers and graphite fiber differ. The basic differences lie in the temperature at which the fibers are made and heat treated, and in the amount of elemental carbon produced. Carbon fibers typically are carbonized in the region of 1315° C (2400° F) and assay at 93 to 95% carbon while graphite fibers are graphitized at 1900° to 2480° C (3450° to 4500° F) and assay at more than 99% elemental carbon.

Carbonization

The process of pyrolysis in an inert atmosphere at temperatures ranging from 800° to 1600° C (1470° to 2910° F) and higher, usually about 1315° C (2400° F). Range is influenced by precursor, individual manufacturer’s process, and properties desired.

Card

A machine used in the manufacture of staple yarns. Its functions are to separate, align, and deliver the fibers in a sliver form and to remove impurities. The machine consists of a series of rolls, the surfaces of which are covered with many projecting wires or metal teeth. Short staple systems employ flat strips covered with card clothing rather than small rolls.

Carding

A process in the manufacturing of spun yarns whereby the staple is opened, cleaned, aligned, and formed into a continuous, untwisted strand called a sliver.

Caterpillar

A large slub formed in a combination or plied yarn as a result of one of the ends breaking and sliding or skinning back along the other yarn.

Cavity

The space inside a mold in which a resin or molding compound is poured or injected.

Chafed End

A warp end that has been abraded during processing. It generally appears as a dull yarn often containing broken filaments.

Circular Knitting Machine

A type of knitting machine which forms a knitted fabric in a cylindrical fashion. Most fabrics formed from circular knitting machines are weft knit structures.

Coalesced Filaments

Filaments stuck together by design or accident during the extrusion process.

Cockling

A crimpness or pucker in the yarn or fabric usually caused by the lack of uniform quality in the raw material used, improper tension on yarn in weaving, or weaving together yarns of different numbers.

Collimated Roving

Roving that has been made using a special process (usually parallel wound), so that the strands are more parallel than in standard roving

Combed Sliver

A continuous band of untwisted fiber, relatively free of short fibers and trash, produced by combing card sliver.

Commingled Yarns

In aerospace textiles, two or more continuous multifilament yarns, the filaments of which have been intermixed with each other without adding twist or otherwise disturbing the parallel relationship of the combined filaments. Usually consists of reinforcing yarn, such as graphite or glass, and a thermoplastic matrix yarn.

Compression Molding

A mold that is open when the material is introduced and that shapes the material by the pressure of closing by heat.

Cone

A conical package of yarn, usually wound on a disposable paper core.

Conjugate Fiber

A two component fiber with specific ability to crimp on hot or hot/wet treatment because of different shrinkage.

Core Spinning

The spinning process for fabricating a core-spun yarn. This consists of feeding a core yarn (which could be an elastomeric filament yarn, a regular filament yarn, a textured yarn, or a previously spun yarn) into the front delivery roll of the spinning frame and of covering the core yarn with a sheath of fibers during the spinning operation.

Count

1. The numerical designation of yarn size indicating the relationship of length to weight. (Also see Yarn Number.) 2. The number of warp yarns (ends) and filling yarns (picks) per inch in a woven fabric, or the number of wales and courses per inch in a knit fabric. For example, a fabric count of 68×52 indicates 68 ends per inch in the warp and 52 picks per inch in the filling.

Course

The row of loops or stitches running across a knit fabric, corresponding to the filling in woven fabrics.

Cover

1. The degree of evenness of thread spacing. 2. The degree to which underlying structure is concealed by the surface material, as in carpets, the degree to which a pile covers backing. 3.The ability of a dye to conceal defects in a fabric.

Cover Factor

The fraction of the surface area that is covered by yarns assuming round yarn shape. An areal ratio of projected fabric surface area to nominal surface area.

Cowoven Fabric

In aerospace textiles, a fabric in which a reinforcing fiber and matrix fiber are adjacent to each other as one end in the warp and/or filling direction.

Crash

A course fabric with a rough, irregular surface made from thick, uneven yarns.

Creel

1. A framework arranged to hold slivers, rovings, or yarns so that many ends can be withdrawn smoothly and evenly without tangling. 2. A similar device used to aggregate sub-tows to tows in manufactured staple processing, especially polyester.

Crimp

The waviness of a fiber expressed as crimp per unit length, calculated as the ratio of arc length to modular length 2. The difference in distance between two points on an unstretched fiber and the same two points when the fiber is straightened under specified tension. Crimp is expressed as a percentage of the unstretched length. 3. The difference in distance between two points when the yarn has been removed from the fabric and straightened under specified tension, expressed as a percentage of the distance between the two points as the yarn lies in the fabric.

Denier

A weight per unit length measure of any linear material. Formally, it is the number of 0.05 gram weights in a 450-meter length. This is numerically equal to the weight in grams of 9,000 meters of the material. Denier is a direct numbering system in which the lower numbers represent the finer sizes and the higher numbers the coarser sizes.

Denier per filament (dpf)

The denier of an individual continuous filament or an individual staple fiber if it were continuous. In filament yarns, it is the yarn denier divided by the number of filaments.

Yarn Denier

The denier of a filament yarn It is the product of the denier per filament and the number of filaments in the yarn.

Total Denier

The denier of a tow before it is crimped. It is the product of the denier per filament and the number of filaments in the tow. The total denier after crimping ( called crimped total denier) is higher because of the resultant increase in weight per unit length.

Dent

On a loom, the space between the wires of a reed.

Dial

In a circular/knitting machine, a circular steel plate with radially arranged slots for needles. A knitting machine equipped with both a dial and a cylinder (q.v.) can produce double-knit fabrics.

Dimensional Stability

The ability of a textile material to maintain or return to it’s original geometric configuration.

Distortion

In a fabric, the displacement of fill fiber from the 90 angle (right angle) relative to the warp fiber. In a laminate, the displacement of the fibers ( especially at radii), relative to their idealized location, due to motion during lay-up and cure.

Doff

To replace empty bobbins with a set of full bobbins. 2. A set of full bobbins produced by one machine ( a robing frame, a spinning frame, or a manufactured filament-yarn extrusion machine).

Doffer

The last or delivery cylinder of the card from which the sheet of fibers is removed by the doffer comb. 2. An operator who removes full bobbins, spools, containers, or other packages from a machine and replaces them with empty ones.

Double-cloth

Two fabrics are woven in the loom at the same time, one fabric on top of the other, with binder threads holding the two fabrics together. The weave on the two fabrics can be different.

Double-knit

A fabric produced on a circular-knitting machine equipped with two sets of latch needles situated at right angles to each other ( dial and cylinder).

Double weave

A fabric with two systems of warp or filling threads so combined that only one is visible on either side. Cutting the yarns that hold the two cloths together yields two separate cut-pile fabrics.

Doubling

A process for combining several strands of sliver, roving, or yarn in yarn manufacturing. 2. The process of twisting together two or more singles or plied yarns, i.e., plying.

Doubling

3. A British term for twisting. 4. The term doubling is sometimes used in a sense opposite to singling. This is unintentional plying. 5. A yarn, considerably heavier than normal, produced by a broken end becoming attached to and twisting into another end.

Draft

In weaving, a pattern or plan or drawing in.

Drawing

The process of attenuating or increasing the length per unit weight of laps, slivers, slubbings, rovings. 2. The hot or cold stretching of continuous filament yarn or tow to align and arrange the crystalline structure of the molecules to achieve improved tensile properties.

Drop stitch

An open design made in knitting by removing some of the needles at set intervals.

Drop stitch

A defect or missed stitch in knitting

End

An individual warp yarn. A warp is co posed of ends. 2. An individual sliver, slubbing, roving, yarn, thread, or cord. 3. A short length or remnant of fabric.

End count

An exact number of ends supplied on a ball of roving.

Entangling

A method of forming a fabric by wrapping and knotting fibers in a web about each other, by mechanical means, or by the use of jets of pressurized water, so as to bond the fibers.

Fabric Crimp

The angulation induced between a yarn and a woven fabric via the weaving or braiding process.

Fabricating

The manufacture of products from molded parts, rods, tubes, sheeting, extrusions, or other form by appropriate operations, such as punching, cutting, drilling, and tapping.

Fabric Crimp Angle

The maximum acute angle of a single weaving yarn’s direction measured from a plane parallel to the surface of the fabric.

Fabric Fill Face

The side of the woven fabric where the greatest number of the yarns are perpendicular to the selvage

Fabric Warp Face

The side of the woven fabric where the greatest number of the yarns are parallel to the fabric.

Face

The correct or better-looking side of the fabric.

Fasciated Yarn

Yarns consisting of a core of discontinuous fibers with little or no twist and surface fibers wrapped around the core bundle.

Fiber Architecture

The spatial arrangement of fibers in the preform. Each architecture has a definite repeating unit.

Fiber Distribution

In a web, the orientations (random or parallel) of fibers and the uniformity of their arrangement.

Fiber Placement

In general, refers to how the plies are laid into their orientation, i.e., by hand, by a textile process, by tape layer, or by a filament winder. Tolerances and angles are specified. Microprocessor-controlled placement that gives precise control of each axis of motion permits more intricate · winding patterns than are possible with conventional winding and is used to make composites that are more complex than usual filament-wound structures.

Fiber Wash

Splaying out of woven or nonwoven fibers from the general reinforcement direction. Fibers are carried along with bleeding resin during cure.

Fibrets

Very short fine (diameter 50 microns) fibrillated fibers that are highly branched and irregular resulting in very high surface area.

Fibrillation

Massive amounts of fly produced braiding process due to friction and abrasion applied to the yarns. The source of friction is other yarns and the rings and hooks over which the yarns travel. In severe cases, may cause jamming of the braiding machine if not corrected.

Filament

The smallest unit of a fibrous material. The basic units formed during drawing and spinning , which are gathered into strands of fiber for use in composites. Filaments usually are of extreme length and very small diameter, usually less than 25 micrometers ( 1 mil.)

Filling

In a woven fabric, the yarn running from selvage to selvage at right angles to the warp. Each crosswise length is called a pick. In the weaving process, the filling yarn is carried by the shuttle or other type of yarn carrier.

Finishing

All the processes through which fabric is passed after bleaching, dyeing, or printing in preparation for the market use. Finishing includes such operations as heat-setting, napping, embossing, pressing, calendering, and the application of chemicals that change the character of the fa.bric. The term finishing is also sometimes used to refer collectively to all processing operations above, including bleaching, dyeing, printing, etc.

Flat knit fabric

A fabric made on a flatknitting machine, as distinguished from tubular fabrics ma.de on a circular-knitting machine. While tricot and milanese warp-knit fabrics (non run) are knit in flat form, the trade uses the term flat-knit fabric to refer to weft-knit fabrics made on a flat machine, rather than warpknit fabrics. 2. A term used in the underwear trade for plain-stitch fabrics made on a circularknitting machine. These fabrics have a flat sur face and are often called flat-knit to differentiate them from rib-knit or Swiss rib fabrics. In this case, the term refers to the texture, not the type of machine on which the fabric was knit.

Flat knitting machine

A weft knitting machine with needles arranged in a straight line in a flat plate called the bed. The yarn travels alternately back and forth, and the fabric may be shaped or varied in width, as desired, during the knitting process. Lengthwise edges are selvages. Flat-knitting machines may be divided into two types: latch-needle machines for sweaters, scarves, and similar articles and fine spring-needle machines for full fashioned hosiery.

Float

The portion of a warp or filling yarn that extends over two or adjacent filling picks or warp ends in weaving for the purpose of forming certain designs. 2. In a knit fabric, a portion of yarn that extends for some length without being knitted in. 3. a fabric defect consisting of an end lying or floating on the cloth surface instead of being woven in properly. Floats are usually caused by slubs, knot-tails, knots, or fly waste, or sometimes by ends being drawn in heddle eyes incorrectly or being twisted around heddle wires.

Flocking

A method of cloth ornamentation in which adhesives printed or coated on a fabric, and finely chopped are applied all over by means of dusting, air-blasting, or electrostatic attraction. In flock printing, the fibers adhere only to the printed areas and are removed from the unprinted areas by mechanical action.

Fly

The short waste fibers that are released into the air in textile processing operations such as picking, carding, spinning and weaving.

Fraying

The slipping or raveling of yarns from unfinished edges of cloth

Gabardine

A firm, durable, warp-faced cloth, showing a decided twill line of 45 or 63 degrees right-hand twill.

Graphite

The crystalline allotrophic form of carbon

Graphite fiber

A fiber made from a precursor by an oxidation, carbonization, and graphitization process. See also Carbon Fiber.

Greige Fabric

An unfinished fabric just off the loom or knitting machine

Grinning

1. A flaw in fabric, especially a ribbed fabric, that occurs when warp threads show through the covering filling threads or when the threads have slipped leaving open spaces on either side. 2. A condition that occurs when the carpet backing shows through the pile. 3. A printing term referring to either poor cover where the background shade shows through the print, or to the “two-tone” appearance of a shade printed with incompatible dyes.

Gripper Loom

Shuttleless looms. These looms employ a projectile with a jaw that grips the end of the filling yarn during the insertion of the pick.

Hand

The tactile qualities of a fabric such as softness, firmness, elasticity, fineness, resilience, and other qualities perceived by touch.

Hank

1. A skein of yarn. 2. A standard length of slubbing, roving, or yarn. The length is specified by the yarn numbering system in use; e.g., cotton hanks have a length of 840 yards. 3. A term applied to slubbing or roving that indicates the yarn number (count); e.g., a 1.5 hank roving.

Harness

A frame holding the heddles in position in the loom during weaving.

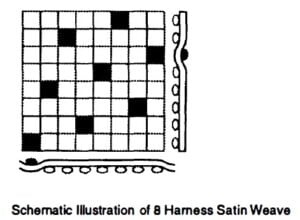

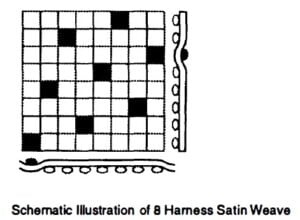

Harness Satin

Weaving pattern producing a satin appearance. “Eight-harness” means the warp tow crosses over seven fill tows and under the eighth (repeatedly).

Heddle

A cord, round steel wire, or thin flat steel strip with a loop or eye near the center through which one or more · warp threads pass on the loom so that the thread movement may be controlled in weaving. The heddles are held at both ends by the harness frame. They control the weave pattern and shed as the harnesses are raised and lowered during weaving.

Helical Winding

In filament wound items, a winding in which a filament band advances along a helical pa.th, not necessarily at a constant angle except in the case of a cylinder.

High Bulk Yarn

Qualitative term to describe a textured yarn. A hulked yarn develops more hulk than stretch in the finished fabric.

Highloft

General term for a fiber structure containing more air than fiber. Specifically, a lofty, low-density nonwoven structure that is used for applications such as fiberfill, insulation, health care, personal protection, and cleaning materials.

Hispidulous Yarn

A yarn which has a “hairy” surface. Generally intended for yarn-yarn interlocking when fabricating composite preforms.

Hot head press

A pressing machine capable of generating high temperatures and pressures. Used for pressing and processing permanent press fabrics

Hybrid Composite

Advanced composite with a combination of different high-strength continuous filaments in the matrix. Also, composite in which continuous and staple fibers are used in the same matrix.

Hybrid Fabric

Fabric for composite manufacture in which two or more different yarns are used in the fabric construction. This provides design flexibility to meet performance requirements and controls cost by permitting some lower priced fibers to be used.

Hybrid Yarn

In aerospace textiles, a yarn having more than one component

Imbibition

A measure of the liquid or water holding capacity of a textile material.

Impregnated Fabric

A fabric in which the interstices between the yarns are completely filled, as compared to size or coated materials where the interstices are not completely filled. Not included in the definition is a woven fabric constructed from impregnated yarns, rather than one impregnated after weaving.

Interlock Knit

To produce an interlock knit, long and short needles are arranged alternately in both the dial and cylinder; the needles in the dial and cylinder are also positioned in direct alignment. When the long and short needles knit in alternate feeds in both housings, a fabric with a type of cross 1 x 1 rib effect is produced.

Intermingling

1. Use of air jets to create turbulence to entangle the filaments of continuous yarns, without forming loops, after extrusion. Provides dimensional stability and cohesion for further processing but is not of itself a texturing process. It is compatible with high-speed spindrawing and high-speed take-up. When compared with twisting processes, it also permits increased take-up package size. 2. Combining two or more yarns via an intermingling jet. Can be used to get special effect yarns, i.e., mixing dye variants to get heather effects upon subsequent dyeing.

Jacquard

A system of weaving that utilizes a highly versatile pattern mechanism to permit the production of large, intricate designs. The weave pattern is achieved by a series of punched cards. Each card perforation controls the action of one warp thread for the passage of one pick. The machine may carry a large number of cards, depending on the design, because there is a separate card for each- pick in the pattern.

Jersey

A circular knit or flat knit fabric made with a plain stitch in which the loops intermesh in only one direction. As a result, the appearance of the face and the back of a jersey fabric is wholly different. 2. A tricot fabric made with a simple stitch, characterized by excellent drape and wrinkle recovery properties.

Jet Loom

A shuttleless loom that employs a jet of water or air to carry the filling yarn through the shed.

Kevlar

Trade name for an organic polymer composed of aromatic polyamides having a paratype orientation (parallel chain extending bonds from each aromatic nucleus). Developed at DuPont. Kevlar is known for its high specific strength and toughness.

Knitting

A method of constructing fabric by interlocking series of loops of one or more yarns. The two major classes of knitting are warp knitting and weft knitting

Warp Knitting

A type of knitting in which the yarns generally run lengthwise in the fabric. The yarns are prepared as warps on beams with one or more yarns for each needle. Examples of this type of knitting are tricot, milanese, and raschel knitting.

Milanese Knitting

A type of run resistant warp knitting with a diagonal rib effect using several sets of yarns.

Rachel Knitting

A versatile type of warp knitting made in plain and jacquard patterns; the latter can be made with intricate eyelet and lacy patterns and is often used for underwear fabrics. Raschel fabrics are coarser than other warp-knit fabrics, but a wide range of fabrics can be made. Raschel knitting machines have one or two sets of latch needles and up to thirty sets of guides.

Tricot Knitting

A run resistant type of warp knitting in which either single or double sets of yarn are used.

Weft Knitting

A common type of knitting in which one continuous thread runs crosswise in the fabric making all of the loops in one course. Weft knitting types are circular and flat knitting.

Circular Knitting

The fabric is produced on the knitting machine in the form of a tube, the threads running continuously around the fabric.

Flat Knitting

The fabric is produced on the knitting machine in flat form, the threads alternating ha.ck and forth across the fabric. The fabric can be given shape in the knitting process by increasing or decreasing loops.

Lace Stitch

In this knitting stitch structure, loops a.re transferred from the needles to create a fabric with an open or a raised effect.

Laid-In Fabric

A knit fabric in which an effect yarn is tucked in, not knitted into, the fabric structure. The laid-in yarns a.re held in position by the knitted yarns.

Lap

A continuous, considerably compressed sheet of fibers that is rolled under pressure into a cylindrical package, usually weighing between 40 and 50 pounds. The lap is used to supply the card.

Lase

An acronym for load a specified elongation: the load required to produce a given elongation of a yarn or cord.

Leno Weave

A weave in which the warp yarns are arranged in pairs with one twisted around the other between picks of filling yarn as in marquisette. This type of weave gives firmness and strength to an open-weave fabric and prevents slippage and displacement of warp and filling yarns.

Linear Density

The mass per unit length of a fiber or yarn, typically expressed as grams per centimeter, pounds per foot, or equivalent units. It is a proportion obtained by dividing the mass of a fiber or yarn by its length.

Loom

A machine for weaving fabric by interlacing a series of vertical, or parallel threads (the warp) with a series of horizontal, parallel threads (the filling). The warp yarns from a beam pass through the heddles and reed, and the filling is shot through the “shed” of warp threads by means of a shuttle or other device and is settled in place by the reed and lay. The woven fabric is then wound on a cloth beam. The primary distinction between different types of looms is the manner of filling insertion. The principal elements of any type of loom are the shedding, picking, and beating-up devices.

Long Staple

A long fiber. In reference to cotton a long staple indicates a finer length of not less than 1-1 /8 inches. In reference to wool, the term indicates fiber 3 to 4 inches long suitable for combing.

Longitudinal

Yarns which run in the 0 degree direction of the fabric (warp direction). Can refer to yarns in a 3-D weave, 3-D braid, triaxial braid, or multi-axial warp knit.

Macro-Lattice

A repeating structure in a very small microfibrills of alternating crystalline and amorphous regions. Yarn properties are thought to be governed by morphology at the macro-lattice scale.

Machine Twist

A hard-twist sewing thread, usally of 3-ply construction spun with a S-twist and plied with a Z-twist, especially made for use with sewing machines.

Mandrel

The core around which the filaments or yarns are placed to form a specified shape in composite manufacture. The mandrel constitutes the internal shape of the composite.

Matrix Fiber

A manufactured fiber that is essentially a physical combination or mixture of two or more chemically distinct constituents or components combined at or prior the time of extrusion (i.e., produced in fiber form), with components, if separately extruded, would each fall within different definitions of textile fibers. Matrix fibril fibers have the fibril constituent randomly arranged across the cross section of the matrix.

Metap Weave-Knit Process

A technique combining weaving and knitting in one operation with two independent yarn systems wound on warp beams. In the fabrics produced, woven strips are linked together with wales of stitches. Generally, the fabrics have 75-85% woven and 25-15% knitted structure.

Microdenier

Refers to fibers having less than 1 denier per filament or 0.1 tex per filament.

Milanese Knitting

A type of run resistant warp knitting with a diagonal rib effect using several sets of yarns.

Mold

The cavity or matrix into or on which the plastic composition is placed and from which it takes form.

Molded Edge

The edge that is not physically altered after molding for use in final form, and particularly one that does not have fiber ends along its length.

Molded Net

Description of a molded part that requires no additional processing to meet dimensional requirements.

Mold Shrinkage

The rapid thermal shrinkage that a molded part experiences upon removal from a mold and cooled at room temperature.

Mold Surface

The side of a laminate that faced the mold (tool) during cure in an autoclave or hydroclave.

Monofilament

A single fiber or filament of indefinite length, strong enough to function as a yarn in commercial textile operations.

Napping

A finishing process that raises the surface fibers of a fabric by means of passage over rapidly revolving cylinders covered with metal points or teasel burrs. Outing, flannel, and wool broadcloth derive their downy appearance from this process.

Needle Loom

A machine for bonding a nonwoven web by mechanically orienting the fibers through the web. The process is called needling, or needle punching. Barbed needles set into a board punch fiber into the batt and withdraw, leaving the fibers entangled. The needles are spaced in a nonaligned arrangement. By varying the stroke per minute, the advance rate of the batt, the degree of penetration of the needles, and the weight of the batt, a wide range of fabric densities can be made. For additional strength, the fiber web can be needled to a woven, knit, or bonded fabric. Bonding agents may also be used.

NDE

Nondestructive evaluation

Nondestructive Inspection

A procedure, such as ultrasonic or radiographic inspection for determining the quality or characteristics of a material, part, or assembly, without permanently altering the subject or its properties.

Nonwoven Fabric

An assembly of textile fibers held together by mechanical interlocking in a random web or mat, by fusing of the fibers (in the case of thermoplastic fibers), or by bonding with a cementing medium such as starch, glue, casein, rubber, latex, or one of the cellulose derivatives or synthetic resins. Initially, the fibers may be oriented in one direction or may be deposited in a random manner. This web or sheet of fibers is bonded together by one of the methods described above. Normally, crimped fibers that range in length from 0.75 to 4.5 inches are used.

Optimum Twist

In spun yarns, a term to describe the amount of twist that gives the maximum breaking strength or the maximum bulk at strength levels acceptable for weaving or knitting.

Organzine Yarn

Two or more threads twisted in the singles and the plied in the reverse direction. The number of turns per inch in the singles and in the ply is usually in the range of 10 to 20 turns. Organzine yarn is generally used in the warp.

Packages

A large selection of forms for winding yarn is available to meet the requirements of existing machinery and a variety of package builds is used to ensure suitable unwinding in later stages of manufacturing. Since a package with flanges cannot be unwound easily and quickly by pulling the yarn off over end, most packages are flangeless with self-supporting edges. Some can be unwound at speeds up to 1500 yd/min.

Pick

A single filling thread carried by one trip of the weft-insertion device across the loom. The picks interlace with the warp ends to form a woven fabric.

Pick Count

The number of filling yarns per inch or per centimeter of fabric

Picker

A machine that opens staple fiber and forms a lap for the carding process used in the production of spun yarns. That part of the picking mechanism of the loom that actually strikes the shuttle.

Pile

A fabric effect formed by introducing tufts loops, or other erect yarns on all or part of the fabric surface. Types are warp, filling, and knotted pile, or loops produced by weaving an extra set of yarns over wires that are then drawn out of the fabric. Plain wires leave uncut loops; wires with a razor-like blade produce a cut-pile surface. Pile fabric can also be made by producing a double-cloth structure woven face to face, with an extra. set of yarn interlacing with ea.ch cloth alternately. The two fabrics are cut apart by a. traversing knife, producing two fabrics with a cut-pile face. Pile should not be confused with nap. Corduroys are another type of pile fabric, where long floats a.re on the surface are slit, causing the pile to stand erect.

Pile Weave

A weave in which an additional set of yarns, either warp or filling, floats on the surface and is cut to form a pile.

Plain Weave

One of the three fundamental weaves: plain, satin, and twill. Each filling yarn passes successfully over and under each warp yarn, alternating each row.

Planar Winding

A winding in which the filament path lies on a plane that intersects the winding surface.

Plied Yarn

Yarn made by collecting two or more single yarns.

Ply

In general, fabrics or felts consisting of one or more layers (laminates and so forth). The layers make up a stack. A single layer of prepeg. A single pass in filament winding.

Polar Winding

A winding in which the filament path passes tangent to the polar opening at one end of the chamber and tangent to the opposite side of the polar opening at the other end.

Postcure

Additional elevated temperature cure especially without pressure, to improve final properties and/or complete the cure, or decrease the percentage of volatiles in the compound.

Prefit

A process of checking the fit of mating detail parts in an assembly prior to adhesive bonding, to ensure proper bond lines.

Preform

A preshaped fibrous reinforcement formed by distribution of chopped fibers or cloth by air, water flotation, or vacuum over the surface of a perforated screen to the approximate contour and thickness desired in the finished part. Also, a preshaped fibrous reinforcement of mat or cloth formed to the desired shape on mandrel or mock-up before being placed in a mold press.

Prepreg

Ready to mold, reinforcing material, either fiber, fabric, or mat that is fully impregnated with resin and in some cases, partially cured. Prepregs are then used by fabricators in laying-up and molding composites after which curing is completed.

Press Clave

A simulated autoclave made by using the platens of a press to seal the ends of an open chamber, providing both the force required to prevent the loss of the pressurizing medium and the heat required to cure the laminate inside.

Projective Loom

A shuttleless loom that uses small, bullet-like projectiles to carry the filling yarn through the shed. Fill is inserted from the same side of the loom for each pick. A tucked selvage is formed.

Pucker

Uneven surface caused by differential shrinkage of the yarns in a fabric or differential shrinkage of the fabric and sewing thread.

Purl

1. A knitting stitch that results in horizontal ridges across the fabric. It is made by drawing alternate courses through each side of the fabric. 2. A picot or small loop that edges needlework, lace, or ribbon.

Quilting

The formulation of a large planar fabric by joining small pieces of fabric together. 2. The formation of a fabric by stitching through two pieces of fabric which are separated by a non-woven web. 3. A bonding technique used for nonwovens in which the fibers are connected (bonded) by stitches sewn or knitted through the web.

Rack

A warp-knitting measure consisting of 480 courses. Tricot fabric quality is judged by the number of inches per rack.

Rapier Loom

Looms in which either a double or single rapier (thin metallic shaft with a yarn gripping device) carries the filament through the shed. In a single rapier machine, the yarn is carried completely across the fabric by the rapier. In the double machine, the yarn is passed from one rapier to the other in the middle of the shed.

Raschel Knitting

A versatile type of warp knitting made in plain and jacquard patterns; the latter can be made with intricate eyelet and lacy patterns and is often used for underwear fabrics. Raschel fabrics are coarser than other warp-knit fabrics, but a wide range of fabrics can be made. Raschel knitting machines have one or two sets of latch needles and up to thirty sets of guides.

Reaming

Further plying of a two-ply yarn with a singles yarn. Reaming is not the same as plying three singles yarns in one operation

Resin

A solid or pseudo-solid organic polymeric material, usually of high molecular weight, that exhibits a tendency to flow when subjected to stress. Many resins are two part catalyzed polymeric systems, typically thermosetting.

Resin Pocket

An apparent accumulation of excess resin in a small, localized section visible on cut edges of molded surfaces, or internal to the structure and nonvisible.

Resin-rich Area

Localized area filled with resin and lacking reinforcing material.

Resin-starved Area

A localized area which has insufficient resin, usually identified by low gloss, dry spots, or fiber showing on the surface.

Resin Transfer Molding

A process whereby catalyzed resin is transferred or injected into an enclosed mold in which fibrous reinforcement has been placed.

Reed

A comb like device on a loom that separates the warp yarns and also beats each succeeding filling thread against the already woven. The reed usually consists of a top and bottom rib of wood into which metal strips or wires are set. The space between two adjacent wires is called a dent ( or split) and the warp is drawn through the dents. The fineness of the reed is calculated by the number of dents per inch.

Repeat

The distance covered by a single unit of a pattern that is duplicated over and over, measured by the length of the fabric.

Rib Knit

A double knit fabric in which the wales or vertical rows of stitches intermesh alternately on the face and the back. In other words, odd wales intermesh on one side of the cloth and even wales on the other. Rib-knit fabrics of his type have good elasticity, especially in the width.

Rick Rack

Flat braid in zig zag formation. It is produced by applying different tensions to individual threads during manufacture.

Roving

In spun yarn production, an intermediate state between sliver and yarn. Roving is a condensed sliver that has been drafted, twisted, doubled, and redoubled. The product of the first roving is sometimes called slubbing.

Roving Ball

The supply package offered to the winder, consisting of a number of ends or strands wound to a given outside diameter onto a length of cardboard tube. Usually designated by either fiber weight or length in yards.

Roving Cloth

A textile fabric, coarse in nature, woven from rovings.

S Twist

Direction of yarn twist which gives an “S” like appearance to the yarn. Negative, or lefthand twist.

Satin Weave

One of the basic weaves (plain, satin, and twill). The face of the fabric consists almost completely of warp or filling floats produced in the repeat of the weave. The points of intersection are distributed as evenly and widely separated as possible. Satin weave fabric has a characteristic smooth, lustrous surface and has a considerably greater number of yarns in the set of threads, either warp or filling, that forms the face than in the other set.

Scrim

A lightweight, open-weave, course fabric; the best qualities are made in two-ply yarns. Cotton scrim usually comes, in white, cream, or ecru and is used for window curtains and as backing for carpets. Fabric with open construction used as base fabric in the production of coated or laminated fabric.

Selvage

The narrow edge of woven fabric that runs parallel to the warp. It is made with stronger yarns in a tighter construction than the body of the fabric to prevent raveling. A fast selvage encloses all or part of the picks, and a selvage is not fast when the filling threads are cut at the fabric edge after every pick.

Serge

Any smooth-faced cloth made with a two-up and two-down twill weave.

Served Yarn

In aerospace textiles, a reinforcing yarn such as graphite or glass around which two different yarns are wound.

Set Yarn

False-twist yarns stabilized to produce bulk.

Shaft

A term used with reference to satins indicating the number of harnesses employed to produce the weave.

Shearing

A dry finishing operation in which projecting fibers are mechanically cut or trimmed from the face of the fabric. Woolen and worsted fabrics are almost always sheared. Shearing is also widely employed on other fabrics, especially on napped and pile fabrics where the amount varies according to the desired height of the nap or pile. For flat-finished fabrics such as gabardine, a very close shearing is given.

Sheath-Core Fibers

Bicomponent fibers of either two polymer types, or two variants of the same polymer. One polymer forms a core and the other surrounds it as a sheath.

Shed

A path through and perpendicular to the warp in the loom. It is formed by raising some warp threads by means of their harness while others are left down. The shuttle passes through the shed to insert the filling.

Shedding

The operation of forming a shed in weaving.

Shuttle

A boat shaped device, usually made of wood with a metal tip, that carries filing yarns through the shed in the weaving process. It is the most common weft-insertion device. The shuttle holds a quill, or pin, on which the filling yarn is wound. It is equipped with an eyelet at one end to control rate. The filling yarn is furnished during the weaving operation.

Shuttleless Loom

A loom in which some other device other than a shuttle is used for weft insertion.

Single-Knit Fabric

Also called a plain knit, a fabric constructed with one needle bed and one set of needles.

Singles Yarn

The simplest strand of textile material suitable for operations such as weaving and knitting. A singles yarn may be formed from fibers with more or less twist; from filaments with or without twist; from narrow strips of material such as paper, cellophane, or metal foil; or from monofilaments. When twist is present, it is all in the same direction.

Sizing

A generic term for compounds that are applied to warp yarn to bind the fiber together and stiffen the yarn to provide abrasion resistance during weaving. Starch, gelatin, oil, wax, and manufactured polymers such as ploy-vinyl alcohol, polystyrene, polyacrylic acid and polyacetates are employed.

Sizing Content

The percent of the total strand weight made up by the sizing; usually determined by burning off or dissolving the organic sizing.

Skein

A continuous strand of yarn or cord in the form of a collapsed coil. It may be of any specified length and is usually obtained by winding a definite number of turns on a reel under prescribed conditions. The circumference of the reel on which the yarn is wound is usually 45 to 60 inches.

Skewness

The distance measured parallel to and along a selvage between the point at which a filling yarn meets this selvage and perpendicular to the selvage from a point at which the filling yarn meets the other selvage. Skewness may be expressed directly in inches or as a percentage of the width of the fabric at the point of measurement.

Slasher

A machine used to apply size to the warp ends, while transferring the warp yarns from section beams to the loop beam.

Sleeving

A braided, knit, or woven product or fabric in tubular or cylindrical form that is less than 4 inches in width (i.e., 8 inches in diameter)

Sley

The number of warp yarns per inch in a woven cloth on or off the loom.

Sliver

A continuous strand of loosely assembled fibers without twist. Sliver is delivered by the card, the comber, or the drawing frame. The production of sliver is the first step in the textile operation that brings staple fiber into a form that can be drawn (reduced in bulk) and eventually twisted into a spun yarn.

Spectra

Highly oriented polyethylene fibers produced by Allied.

Spinneret

A metal disc containing numerous minute axial holes, used in manufactured fiber extrusion. The spinning solution or melted polymer is forced through the holes to form the fiber filaments.

Spinning

The process or processes used in the production of singles yarns or of fabrics generated directly from polymer.

Yarn from Staple Fiber

The formation of a yarn by a combination of drawing or drafting and twisting prepared strands of fibers, such as rovings.

Filament Yarn

In the spinning of manufactured filaments, fiber forming substances in the plastic or molten state, or in a solution, are forced through fine orifices in a metallic plate called a spinneret, or jet, at a controlled rate. The solidified filaments are drawn-off by rotating rolls, or godets and wound onto bobbins or pirns.

Dry Spinning

A process in which a solution of the fiber-forming substance is extruded in a continuous stream into a heated chamber to re-move the solvent, leaving the solid filament, as in the manufacture of acetate.

Gel Spinning

A spinning process in which the primary mechanism of solidification is the gelling of the polymer solution by cooling to form a gel filament consisting of precipitated polymer and solvent. Solvent removal is accomplished following solidification by washing in a liquid bath. The resultant fibers can be drawn to give a product with the highest tensile strength and modulus.

Melt Spinning

A process in which the fiber-forming substance is melted and extruded into air or other gas, or into a suitable liquid, where it is cooled and solidified, as in the manufacture of polyester and nylon.

Phase-Separation Spinning

A fiber extrusion process of polymer and solvent at high temperature into a cooling zone. During the cooling process, a phase separation occurs, usually accompanied by crystallization of the solvent. Solvent can be removed before or after drawing.

Reaction Spinning

Process in which an initial prepolymer is formed and then extruded into a reagent bath where polymerization and filament formation occur simultaneously. Spandex fibers can be ma.de by this process.

Spiral Yarns

Specialty yarns made by winding heavier, slacky, twisted yarn around a finer yarn with a hard twist to give a slub-like appearance.

Splicing

The joining of two ends of yarn or cordage by interweaving the strands.

Spool

A flanged wooden or metal cylinder upon which yarn, thread, or wire is wound. The spool has an axial hole for a pin or spindle used in winding.

Spun-Bound Product

Nonwoven fabrics form by filaments that have been extruded, drawn, then laid on a continuous belt. Bonding is accomplished by several methods such as by hotroll calendering or by passing the web through a saturated-steam chamber at an elevated pressure.

Spunlace Fabric

A nonwoven fabric produced by entangling fibers in a repeating pattern to form a strong fabric free of binders.

Spun Yarn

A yarn consisting of staple fibers usually bound together by twist or a melt spun fiber before it is drawn.

Staple

Natural Fibers or cut lengths from filaments. Manufactured staple fibers are cut to a definite length, from 8 inches down to about 1-1/2 inches, so that they can be processed on cotton, woolen, or worsted yarn spinning systems.

Starved Area

An area in a plastic part that has an insufficient amount of resin to wet out the reinforcement completely. This condition may be due to improper wetting, impregnation, or resin flow; excessive molding pressure; or improper bleeder cloth thickness.

Starved Joint

An adhesive that has been deprived of the proper film thickness of adhesive due to insufficient adhesive spreading or to the application of excessive pressure during the lamination process.

Sticker

A distortion in the weave characterized by tight and slack places in the same warp yarns. The principle causes are rolled ends on the beam, warp ends restricted by broken filament slubs, and knots catching at lease rods, drop wires, heddles or reeds.

Stitching

The process of passing a fiber or through the thickness of fabric layers to secure them. In composite manufacture, stitching is used to make preforms or to improve damage tolerance of complex-shaped parts.

Stops

Metal pieces inserted between die halves. Used to control the thickness of a press-molded part.

Stretch Breaking

In conversion of tow-to-top fibers are hot stretched and broken rather than cut to prevent some of the damage done by cutting.

Stuffer Box

A mechanism for crimping in which a fiber bundle (e.g., tow or filament yarn) is jammed against itself; causing it to crimp. By the suitable application of heat (usually wet steam) and pressure to the stuffed tow, a high and permanent crimp can be forced into the bundle.

Stuffers

Extra yarns running the warp direction through a woven fabric to increase the fabrics strength and weight.

Take-Up (twist)

The change in length of a filament, yarn, or cord caused by twisting, expressed as a percentage of the original ( untwisted) length.

Take-Up (yarn in fabric)

The difference in distance between two points in a yarn as it lies in a fabric and the same two points after the yarn has been removed from the fabric and straightened under specified tension, expressed as a percentage of the straightened length.

Tenacity

The tensile strength when expressed as force per unit linear density of the unstrained specimen.

Tenter Frame

A machine that dries fabric to a specified width under tension. The machine consists essentially of a pair of endless chains on horizontal tracks. The fabric is held firmly at the edges by pins or clips on the two chains that diverge as they advance through the heated chamber, adjusting the fabric to the desired width.

Tex

A unit for expressing linear density, equal to the weight in grams of 1 kilometer of yarn, filament, fiber, or other textile strand.

Textured Yarn

Yarns that develop stretch and bulk on subsequent processing.

Texturing

The process of crimping, imparting random loops or otherwise modifying continuous filament yarn to increase cover, resilience, abrasion resistance, warmth, insulation and moisture absorption or to provide a different surface texture.

Thread Count

The number of yarns (threads) per inch in either the lengthwise (warp) or crosswise (weft or fill) direction of woven fabrics.

Three-Dimensional Braiding

A fabric structure formed by the intertwining of yarns in a single basic direction. 3-D Braids can be formed in rectangular or cylindrical shapes, generally following the overall shape of the supporting loom. Longitudinal yarns can be introduced into the structure easily. Transverse yarns (either Y or Z) can be entered into the structure with additional operational processes. “2-step Braiding” is a special type of 3-D braiding, as are biaxial and triaxial braiding.

Three-Dimensional Weaving

A fabric formation process used to produce three-dimensional textiles. The yarns are simultaneously woven in three directions (length, width, and thickness) rather than in the conventional two. The fabric is formed of three basic components, longitudinal (axial), filling, and “weavers.”

Types of 3D Weaving

Contoured Fabrics, Expandable Fabrics, Interwoven Fabrics, Contoured Interwoven Fabrics

Through Thickness Braiding

A trade name for 3D braiding by Atlantic Research Co.

Tooling Resin

Resins that have applications as tooling aids, coreboxes, prototypes, hammer forms, stretch forms, foundry patterns, and so forth. Epoxy and silicon are common examples.

Tool Side

A side of the part that is cured against the tool (mold or mandrel)

Tow

A large strand of continuous manufactured fiber filaments without definite twist, collected in a loose, rope-like form, usually held together by crimp. Tow is the form most manufactured fiber reaches before being cut into staple.

Tracker

A fiber, tow, or yarn added to a prepreg for verifying fiber alignment, and in the case of woven materials, for distinguishing warp fibers from fill fibers.

Triaxial Weave

A type of woven fabric which is formed through the placement of three distinct yarn orientations. There are two types of triaxial weaves, those with 1 warp and two wefts, and a new generation of machines which uses 2 warps and one weft.

Tricot

A generic term for the most common type of warp-knit fabric. It has fine wales on the face and coursewise ribs on the back. It can be made in a plain jersey construction or in many other designs.

Twaron

An aramid fiber produced in Europe

Twill Weave

A fundamental weave characterized by diagonal lines produced by a series of floats staggered in the warp-wise direction. The floats are normally formed by filling (fillingfaced twill). A warp face twill is a weave in which the warp yarns produce the diagonal effect.

Twist

The number of turns about its axis per unit of length of a yarn or other textile strand. Twist is expressed as turns per inch (tpi) or turns per cm (tpc).

Twist (direction)

The direction of twist in yarns and other textile strands, as indicated by the capital letters S and Z, in reference to whether the twist direction conforms to the middlesection slope of the particular letter.

Twist Multiplier

The ratio of turns per inch to the square root of the yarn count.

UniWeave

A type of plain weave fabric wherein the warp direction consists of load bearing carbon yarns, and the fill direction contains a small amount of glass fiber. Generally the amount of glass fiber is less than 10%.

Unit Cell

The smallest repeating volume of a material which fully characterizes the structure. The unit cell may depend upon the property under examination (e.g. geometrical unit cells may be different than mechanical response unit cells).

Variability

Variability refers to a distribution of measured properties within a given process. Variability can be measured in terms of geometrical, physical or mechanical response. Typically variability is used to describe some apparently random aspect of the manufacturing process.

Wale

In knit fabrics, a column of loops lying lengthwise in the fabric. The number of wales per inch is a measure of the fineness of the fabric. 2. In woven fabrics, one of the series of ribs, cords, etc., running either warp-wise or fillingwise.

Warp

A yarn running lengthwise in a fabric. A group of yarns in long lengths and approximately parallel.

Warp Knit Fabric

A fabric that is formed with the knitting yarns running lengthwise (warpwise).

Weave

The particular manner in which a fabric is formed by interlacing yarns.

Weavers

The yarns which run in the warp thickness plane of a three dimensional fabric. These are the yarns which hold the longitudinal and filling yarns together.

Weft

The transverse threads or fibers in a woven fabric. Those fibers running perpendicular to the warp. Also called fill or filling yarn.

Weft Insertion

Any of the various methods shuttle, rapier, water jet, etc., for making a pick during a weave.

Welt

1. A finished edge on knit goods, especially hosiery. 2. A small cord covered with fabric and sewn along a seam or boarder to add strength.

Wet Laid Nonwoven

Fabric made by the wet forming process. The short fibers typically have more random orientation in the web and the web has more isotropic properties than carded webs.

Wind Angle

The angular measure in degrees between the direction parallel to the filaments and an established reference.

Woven Fabric

A material (usually a planar structure) constructed by interlacing yarns, fibers, or filaments, to form such fabric patterns as plain, harness satin, or leno weaves.

Woven Roving

A heavy glass fiber fabric made by weaving roving or yarn bundles.

Wrinkle

A surface imperfection in laminated plastics that has the appearance of a crease or fold in one or more outer sheets of the paper, fabric or other base which has been pressed in.

Yarn

An assembling of twisted filaments, fibers, or other strands, to form a continuous length that is suitable for use in weaving or interweaving into textile materials.

Yarn Number

A relative measure of the fineness of yarns. Two classes of systems are in use: Direct yarn number (equal to linear density) in the mass per unit length of yarn. Alternatively, indirect yarn number (equal to the reciprocal of linear density) is the length per unit mass of yarn.

Z Twist

Direction of yarn twist which gives a “Z” like appearance to the yarn. Positive twist, or right-hand twist.

Pastore – Textiles Definitions